“These new controllers enable lighting engineers to create customised dynamic LED lighting animations tailored to their system requirements,” according to the company. “They feature integrated non-volatile memory to store animation sequences and LED parameters, essential for dynamic lighting effects such as colour transitions, pulsing, fading and animated patterns.”

- IS31CS8979 is a -40 to +85°C industrial-commercial part

- IS32CS8979 is a -40 to +125°C automotive part with optional AEC-Q100 PPAP

Both come in a 6 x 6mm QFN-40 package, the automotive version in a WFQFN-40 with wettable flanks.

The parts are functionally identical (see note below)

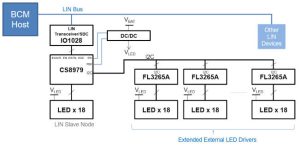

They include an 18-channel independently programmable LED driver that can deliver up to 60mA per channel, which can be paralleled for more current. LED outputs are 40V tolerant, allowing long strings of LEDs to be driven.

They also include an I2C bus through which further LED drivers can be controlled – the company suggests its multiple instances of its own IS3xFL3265x series ICs, which will also each drive up to 18 LEDs at up to 60mA (and look very much like the new parts minus the internal MCU).

Multiple IS3xCS8979 (the new parts) can also be cascaded to support up to 15 additional LED drivers, with synchronisation limited by the code space, said Lumissil.

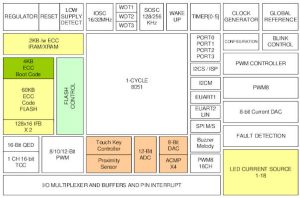

64kbyte of ECC-protected flash is provided to store animation sequences, the playing of which can be triggered by external signals detected on the nine available GPIO pads.

The MCU, which the company said has “DSP functionality” and can “perform complex color space conversions, brightness transitions and colour pattern animations”, also has 2kbyte of ECC-protected SRAM and supports in-system programming.

General functions include a 12bit SAR ADC, flexible PWM generation, multiple timer-counters, a 16bit quadrature decoder, a UART and a LIN interface (that can also function as a second UART).

Electronics Weekly asked Lumissil how the two parts differ.

Its reply indicates:

- That the die are the same and there is no electronic functional difference.

- Physically, the automotive version has the wettable-flan package, which allows automated optical inspection, and gives it slightly better heat transfer characterisitcs – the current industrial version data sheet shows a wettable flank package on the dimension page, but the packaging is actually plain QFN-40.

- Automotive versions are characterised over a wider temperature range and go thorugh AEC-Q100 qualification. During production, they are tested over a wider temperature range, and to tighter tolerances.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News