“As we move the Intel 4, Intel 3 capacity into Ireland, it also gives our TD (technical development) team more focus on their capital on 18A as well as then 14A and 10A, and we’re taking, for instance, the second high NA tool is coming into our Oregon facility,” said Intel CEO Pat Gelsinger last week, “so we’re well underway on 14A. So part of this was a capacity and cost decision for the long term. Part of it was an AI PC acceleration, but it was also a TD cadence decision and optimising the use of our TD resources for the next-generation technologies, which are already well underway and showing good early indicators.”

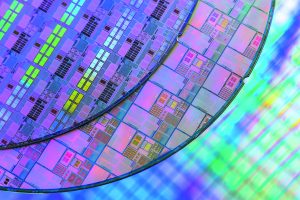

Intel plans to use the $380 million machine in the development of its 14A generation of chips in 2025, with early production expected in 2026 and full commercial production in 2027.

High NA EUV is expected to be able to print features up to 1.7x smaller than existing EUV tools. This will enable 2D feature scaling, resulting in up to 2.9x more density.

Compared to 0.33NA EUV, High NA EUV (or 0.55NA EUV) can deliver higher imaging contrast for similar features, which enables less light per exposure, thereby reducing the time required to print each layer and increasing wafer output.

Intel expects to use both 0.33NA EUV and 0.55NA EUV alongside other lithography processes in developing and manufacturing ICs, starting with product proof points on Intel 18A in 2025 and continuing into production of Intel 14A.

Intel’s first High NA tool was delivered to Oregon in April. The $373 million machine, the size of a double decker bus and weighing over 150 metric tons, was transported to Oregon in more than 250 crates inside 43 freight containers.

These were loaded onto multiple cargo planes that landed in Seattle. They were then transferred to 20 trucks for the drive to Oregon.

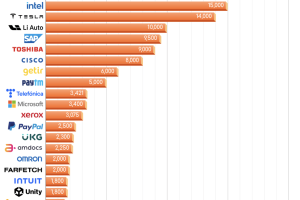

See also: Intel to lay off 15,000 people

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News