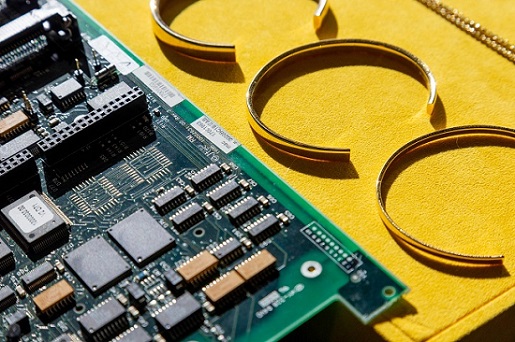

What am I talking about? The picture is supplied by The Royal Mint, which has announced the opening of its processing plant to recover gold from UK electronic wastes.

Up to 4,000 tonnes of PCBs from e-waste will be processed by The Royal Mint annually. The post-processing phase also allows for the plastic elements to be handled appropriately.

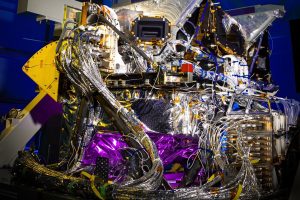

The 3,700 square metre facility is in Llantrisant, South Wales (about six miles from the Sony plant, incidentally that produces the Raspberry Pi for Farnell).

“The Royal Mint is transforming for the future, and the opening of our Precious Metals Recovery factory marks a pivotal step in our journey,” said Anne Jessopp, The Royal Mint’s CEO.

“We are not only preserving finite precious metals for future generations, but we are also preserving the expert craftmanship The Royal Mint is famous for by creating new jobs and reskilling opportunities for our employees.”

What a great initiative. You can read more about the precious metals recovery plant on the Royal Mint website. It’s good to see the UK take action as we are apparently number two, globally, for producing e-waste per capita.

Excir gold

Apparently, The Royal Mint is using patented new techniques created by Excir, a Canadian clean-tech company.

Apparently, The Royal Mint is using patented new techniques created by Excir, a Canadian clean-tech company.

The system works at room temperature, creating a more energy efficient and cost-effective method of gold recovery

“The unique chemistry is capable of recovering over 99% of the precious metals contained within electronic waste – selectively targeting the metal in seconds,” said The Royal Mint.

ISO

The Royal Mint says it has been working with industry bodies to help produce the first standard by the ISO (International Organization for Standardization) for the definition of recycled gold.

According to the United Nations’ Global E-waste Monitor, the generation of worldwide e-waste is increasing by 2.6 million tonnes every year. A record 62 million tonnes of e-waste was produced in 2022, up 82% from 2010. Only 17% of electronic waste is formally recycled.

See also: Gold plating makes silver nanowires last a lot longer

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

I wonder how many grams of gold there are per tonne of waste.

Apparently in hard rock gold mining there’s about 12grams of gold per tonne of rock.

Which makes you think.

Yes, I was looking at first for such a figure, and then I thought the ‘e-waste’ comes in so many shapes and sizes that a standard extraction metric, based on weight, just isn’t possible. A finger in air estimate would still be interesting though.

At the very least they will be disposing of the plastic elements correctly, too.