The device is 5mm wide and consists of five emitters, each 100?m wide with a 4mm long cavity.

Called SPL BF98-40-5, it creates 976nm infra-red at 3W/mm.mrad at an optical output of 44W.

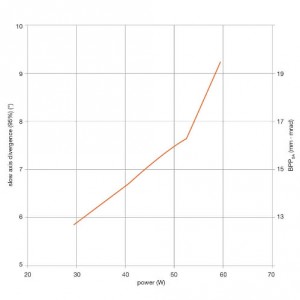

Lateral divergence is between 6° at 30W (95% of power) and approximately 9.5° at 60W.

“Beam quality of a laser is a crucial factor for coupling laser light into optical fibres,” said Osram. “A brilliant light source greatly simplifies the design of the optical system.”

“Beam quality of a laser is a crucial factor for coupling laser light into optical fibres,” said Osram. “A brilliant light source greatly simplifies the design of the optical system.”

Electro-optical efficiency is claimed to be 65% at 44W for easier cooling.

According to the firm. Life tests show an output drop under 1% after 4,000 hours producing 65W with 25°C cooling water.

Fibre-coupled diode laser systems are used in the automobile industry for vehicle chassis welding, soldering and coating.

Laser diodes are also used for pumping metal cutting fibre lasers – 976nm is suited to pumping ytterbium-doped fibres in particular.

Development was assisted by the Germany Ministry for Education and Research (BMBF) HEMILAS project.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News