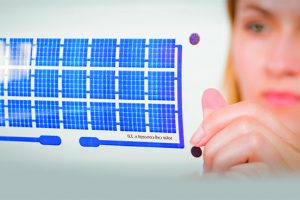

The bendable flexible material can be transferred directly from the melt to a roller for storage, and then be unrolled into a manufacturing line.

Created by a consortium of Schott, Fraunhofer FEP, Tesa SE and Von Ardenne, at 150μm the glass is both bendable and stable, giving it advantages over plastics, metals or silicon in terms of optical quality, temperature stability, chemical consistency, gas porosity or mechanical resistance – and it can be made down to 25µm.

“Printed electronics is an interesting growth market where ultra-thin special glass can represent the optimal substrate for it,” said Schott application engineer Thomas Wiegel.

This is a research project, with challenges to manage and overcome, said Fraunhofer. The team has already made significantly improvements in glass edge strength, and the partners are optimistic that they will be able to bring glass-on-a-roll to market.

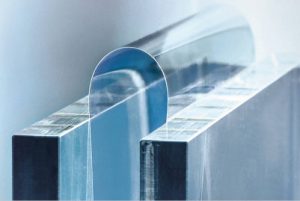

The glass has been developed as part of a German government funded project called Konfekt which not only proposes it as a substrate for electronics, but also as part of a glass-adhesive laminate tape that will serve as a hermetic encapsulation, blocking oxygen and humidity from entering OLEDs, for example.

The idea is that two layers will block water vapour and oxygen from entering the front or rear of the OLED – it is impenetrable even at 10μm thick and pin-hole-free – while a special adhesive will prevent ingress from the edges.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News