Despite only spinning out in January 2020, Porotech claims to have been generating revenue for 10 months and be “working with some of the biggest global names in display technology” – the company launched a commercial native red InGaN LED epi-wafer for micro-LEDs in November 2020.

This funding round was led by Speedinvest, with participation from previous investors IQ Capital, Cambridge Enterprise, Martlet and Cambridge Angels.

This adds to £1.5m seed funding co-led by Cambridge Enterprise and IQ Capital Partners in 2020, which included Martlet Capital and a syndicate of angel investors from Cambridge Angels and Cambridge Capital Group.

Porotech’s intellectual property is built around a class of porous indium gallium nitride on which LEDs of all three primary colours: red, green and blue, can be made on the same wafer with no need for special structuring.

“Porous GaN is basically GaN with tiny holes in it that are a few tens of nanometres across. It’s an entirely new engineered GaN material platform to build semiconductor devices on,” said Porotech CEO and co-founder Dr Tongtong Zhu (pictured). “This type of porous GaN fits within existing industry processes and is robust and flexible enough to be tailored to different applications. We are already seeing demand for our standard and customised porous GaN substrates and micro-LED epiwafers, which we can provide on sapphire and silicon platforms ranging from 100mm to 300mm.”

Why micro-LEDs?

Unlike virtual reality goggles, which are enclosed, augmented reality glasses need to include tiny displays that can compete with sunlight.

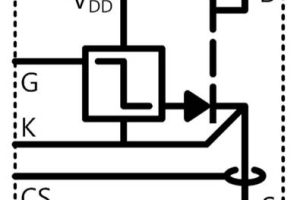

To get such intensity from OLEDs or back-lit LCDs without excessive power consumption, and therefore heat, is proving difficult. As a result, eyes are turning to displays made from arrays of thousands or millions of tiny conventional LEDs – micro-LEDs – as these theoretically have sufficient intensity and efficacy.

Amongst hurdles between now and micro-LED AR glasses are three major ones: maintaining efficacy as the pixel shrinks, building an active matrix under the pixels and producing all three primary colours from the same piece of semiconductor – triple displays around a combining prism is a possible, if expensive, solution to the last of these, but how much more convenient to get all three colours from the same substrate.

“Smart pixels will be our next development,” said Zhu. “Monolithically generated and integrating native self-emissive RGB micro-LEDs on a single wafer to give smaller, lighter, thinner displays that use less energy and offer the greater accuracy required for things like AR gestures.”

Porotech span out of the Cambridge Centre for Gallium Nitride at the University.

Plessey Semiconductors in Devon is another UK company working on micro-LEDs.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News