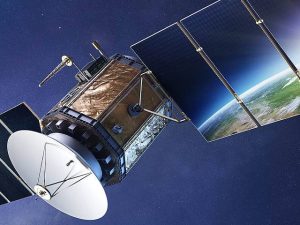

“QML Class P was designed in league with NASA and other industry experts as a plastic packaging standard for space electronic,” TI told Electronics Weekly.

The standard is based on existing SAE standard AS6294.

TI’s QML-P parts are characterised to 50 to 300krad(Si), with lot acceptance testing to 50, 100 or 300krad(Si). Single event latch-up immunity is ≥60MeV.cm2/mg)”

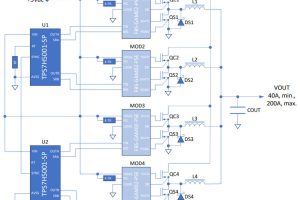

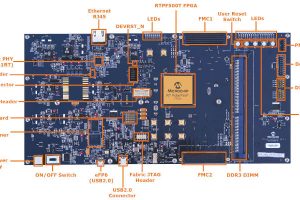

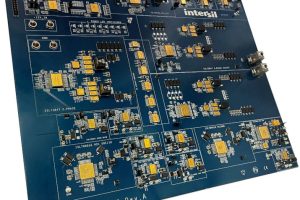

It “enables the use of plastic packaging for power-management, processors, communications and high-speed integrated circuits in satellites, rovers and other spacecraft,” the company said.

Construction wise, TI dictates that only gold wire bonds are used, and that all parts are to undergo 15 thermal cycles between -55 and 125°C followed by 100% x-ray inspection of the bonds. Electrical test is then followed by 240 hours of 125°C burn-in and electrical testing at different temperatures.

Radiation figures are from TI’s Space Products Guide

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News