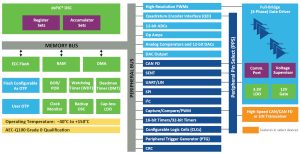

Other members of the family offer LIN transceivers instead of CAN, or a CAN interface without transceivers, or no CAN or LIN, and a base model has a 70MHz processor. Some have SENT interfaces for sensors.

‘dsPIC33CDV’ is the common part prefix, and dsPIC33CDVC256MP506 is one of the two versions that include a CAN FD interface, and has the larger memory of the two: 256kbyte flash and 24kbyte ram.

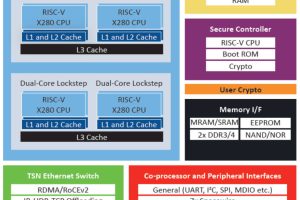

Inside this version, the CPU is based on the dsPIC33CK256MP506, the gate driver on the MCP8021, and the CAN FD transceiver on the ATA6563 – this latter block requires its own 5V rail to be provided from the outside, but the CPU can get 3.3V from an internal linear regulator with runs from up to 29V (40V transients).

The processor is one of the company’s dsPIC33 ‘digital signal controllers’ and it is capable of implementing field-oriented control for motors.

CPU operation is 100MHz from 3 to 3.6V and across -40 to +125°C, then 70MHz up to +150°C. The motor driver will work across 6.5 to 29V and -40 to +150°C.

Peripherals include multiple timers, motor control PWMs with 2ns resolution, a 12bit 3.5Msample/s ADC with 15 channels, three op-amps for the ADC, a 15ns comparator and a 32bit quadrature encoder interface.

Among its serial interfaces are UARTs, 50Mbit/s SPI, I2C host and client, and SENT.

The part is functional-safety-ready (ISO 26262/IEC 61508/IEC 60730) and, for automotive use, compliant to AEC-Q100 REV-H (Grade 1: -40°C to +125°C, Grade 0 to +150°C).

| Product | CPU speed |

CAN FD transceiver |

LIN transceiver |

Program memory |

RAM |

|---|---|---|---|---|---|

| dsPIC33EDV64MC205 | 70MHz | – | – | 64kbyte | 8kbyte |

| dsPIC33CDVL64MC106 | 100 | – | Yes | 64 | 8 |

| dsPIC33CDV64MC106 | 100 | – | – | 64 | 8 |

| dsPIC33CDV128MP206 | 100 | – | – | 128 | 16 |

| dsPIC33CDV128MP506 | 100 | – | – | 128 | 16 |

| dsPIC33CDV256MP206 | 100 | – | – | 256 | 24 |

| dsPIC33CDV256MP506 | 100 | – | – | 256 | 24 |

| dsPIC33CDVC128MP506 | 100 | Yes | – | 128 | 16 |

| dsPIC33CDVC256MP506 | 100 | Yes | – | 256 | 24 |

All versions include three half-bridges, an integrated charge pump to ensure 12V gate drive, and the 3.3V LDO. They work up to 125°C (or 150°C with reduced performance).

Hardware development support comes from a kit that includes: a dsPIC33CK low-voltage motor control development board, a 24V three-phase brush-less dc motor, and an ac-dc adapter. It can support motors across 12 and 48Vdc and up to 10A.

Separately, ‘MCLV-48V-300W’ is a board for powering three-phase permanent magnet synchronous motors rated between 12 and 48Vdc and up to 25Arms/phase. A separate dual-in-line module is inserted to configure it for a particular processor.

‘MotorBench’ is GUI-based software development tool for field-oriented control that can measures motor parameters and automatically tune feedback control gains, subsequently generating source code. v2.45, includes ‘zero-speed/maximum torque’ “which enables designers to eliminate Hall or magnetic sensors while maximising the torque output from the motor, from start-up and at low speeds”, claimed the company.

Added to the company’s existing MPLAB Discover software are Matlab Simulink models supporting various motor control algorithms and development boards.

Automotive applications include cooling fans, gas, oil and water pumps, compressors, valves, actuators, and turbo chargers. Industrial and commercial applications include power tools and other battery powered equipment.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News