Using a som allows engineers to focus on the application layer, where the value-added work is performed

There are five key benefits of a system-on-module (som) approach, which will help engineers through the make vs buy decision process.

Flexibility

Standards defining size, connectors and interfaces play a big role in the flexibility of today’s soms. One versatile platform is SMARC (Smart Mobility ARChitecture), which targets applications requiring low power, low cost and high performance while offering Arm and x86 architectures. Standard-sized modules, such as the popular COM Express and Open Standard modules, are available from multiple suppliers, meaning any module can be plugged into the same socket.

While a som’s architecture typically hits the sweet spot for what most customers need, there are always exceptions. Minor design tweaks to a standard som – such as removing components or changing a memory configuration – are possible without the typical headaches associated with design changes for a chip-down approach.

Streamlined development cycles

Processor subsystem hardware design is not trivial. With chip-down design, design cycles can be 12-24 months or more, requiring a wide range of design expertise and tools. A major advantage of the som approach is time to market. A som’s pre-built computing components have already been laid out, tested and validated, and the platform operating system has already been ported to the board. In most cases, basic certification testing such as RoHS, CE and FCC Class A has already been done. With immediate access to working hardware, a software team can start running and debugging code at the onset. Teams also have access to a board support package that provides the essentials of a working OS or RTOS, as well as example designs and applications.

A design team may want to prototype with a som before jumping straight into production with its own carrier card design. Some som suppliers provide a variety of carrier cards, enabling engineers to be up and running with a som in a matter of minutes. Design files for carriers are often provided, facilitating a quick copy-and-paste of some of the carrier card circuits for use in the customer’s design.

Risk mitigation

Som-based designs are typically easier to implement because all the processing system features are already completed. By outsourcing core computing components to a som provider, design teams hand off the complexities of sourcing multiple components, managing product obsolescence and supply chain management. This is a challenge most engineers ran into headfirst during the recent chip shortage when they could not get the components they needed. Som solutions undergo rigorous testing, ensuring reliability and compatibility, minimising the risk of unforeseen setbacks during development and the potential for failed boards and additional board spins.

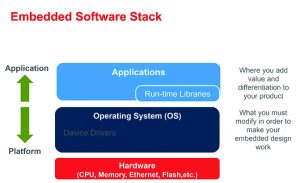

Focus on IP

An important aspect of the som approach is that it frees up engineering time to focus on the more important aspects of the design: the intellectual property. With a chip-down approach, engineers perform substantial work getting the platform layer – the software that makes the system run and enables applications to run on it – to work. While it is an essential part of the system, the platform layer does not directly add value to the end product. A significant amount of this platform development work has been done with a som, therefore engineers can focus their efforts on the application layer to add the most value and to differentiate the product in the marketplace.

Ecosystem expertise

Collaborating with established providers is key to maximising the benefits of using a som. Working with ecosystem partners, including manufacturers and distributors, engineering teams gain access to significant resources and support throughout the development lifecycle. From component selection to post-deployment assistance, strategic partners bring a wealth of design and supply chain expertise to the entire product life cycle.

The som approach to hardware development offers flexibility, efficiency and risk mitigation. These attributes allow engineers to focus on different ways to add market value to their projects, for example, perfecting the platform layer, modifying the OS kernel and adding device drivers and modifying the boot loader.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News