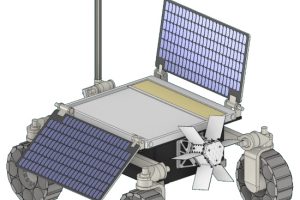

Commercially available polymers and graphites are used and distributed homogeneously to manufacture the plates in any size required. They can shaped after production and embossed to create flow fields for use in fuel cells.

Having flexible bipolar plates made of polymers mean that individual cells do not have to be connected as they currently are. This improves efficiency and manufacturing, compared with the typical cell architecture.

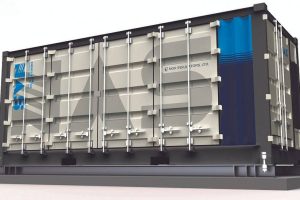

Conventional battery systems can consist of several individual cells, connected by wires. This makes them expense and time-consuming to produce but also means that hot spots can occur. Packaging the cells mean that the battery is bulked out with material that is inactive. Bipolar batteries address these issues by connecting the cells using flat bipolar metal plates. These however, can corrode and ones made of carbon-polymer composite have to be several mm thick.

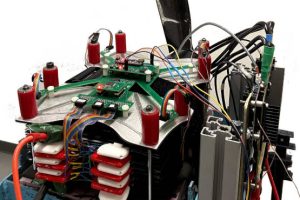

By manufacturing bipolar plates from polymers that have been made electrically conductive, the thickness of the plates is less than conventional cells. There is also a saving of 80% in the material used, said Grevé. The material will not corrode and can be reshaped, allowing embossing for fuel cells. Unlike conventional bipolar plates, these can be welded for a strong, leak-free battery. Whereas conventional plates require joints to be sealed, which can take up space but also become porous, this material can be welded together, seal-free and not allow gases or liquids to pass through.

Researchers are already able to produce sample quantities. The material, in various thickness, will be showcased at the Hannover Fair (1 to 5 April 2019).

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News

The link in your article is totally screwed up. It refers to

http://www,unsicht.frauhofer.de/

The correct URL is

https://www.umsicht.fraunhofer.de/

Apologies – the link has been corrected.