The aerospace sector places some uniquely challenging demands on electronics designers – even compared to other applications where reliability is the key priority.

For a start, the environments that the electronics are exposed to are much harsher than in almost every other scenario. Moreover, the life expectancy of the products is much higher, while the accepted failure rate is easily an order of magnitude lower than typical commercial products.

In fact, the need for ‘bullet-proof’ reliability is absolutely critical and cannot be overstated. With aerospace products, in defence applications particularly, there are no simple return merchandise authorisation processes. You cannot ‘reboot your system to clear issues’ in the middle of a mission on a missile guidance system.

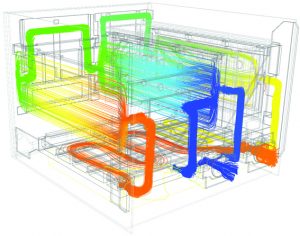

Multi-fluid computational fluid dynamics predicts temperatures and allows mechanical design to be optimised

Product failures always have catastrophic consequences far beyond losing market share, which might be the consequence with a failed consumer electronics device.

When you combine the demand for extremely high reliability with the constant need for higher power and smaller footprints, the result is that thermal design takes on more importance than in other industries.

High-reliability aerospace products are high power-density, tightly‑packed, highly-engineered products, which are exposed to extremely harsh environments. Designers, meanwhile, must find clever ways to dissipate heat from critical components to make sure the electronics meet stringent reliability requirements.

When it comes to ensuring high reliability, thermal design and heat removal are the most critical aspects of aerospace electronics design, there is no way around it, so designers need the tools to deal with these challenges in the most efficient way possible without sacrificing performance or size in the final products.

The case study (below) highlights both the overall importance of thermal design in the high-reliability aerospace sector and the value that more specialised design and simulation tools can deliver to electronics designers.

Where the demands for reliability and performance are high there is simply no way to shortcut the design process – designers need the right tools for the job if they are to complete projects efficiently, accurately and safely.

Case study: Design software models effective thermal management

The work of Ten Tech, provider of design and analysis support for embedded high-reliability defence and aerospace electronics systems, is an example of both the extreme pressures under which aerospace designers work to deal with thermal design, and of the value of simulation in overcoming design challenges.

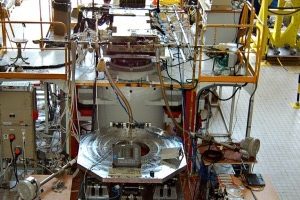

Ten Tech needed to design a liquid-cooled airborne radar processing chassis. This was a high-powered, high-ambient temperature design needing a high level of reliability. It had no cooling mechanism other than the liquid cooling loop. Thermal design was the main driver of the system. A little under 3kW had to be dissipated out to the (already hot) environment to enable the electronics to function reliably.

Ten Tech used 6SigmaET, a dedicated thermal simulation tool, throughout the design process to solve this challenge.

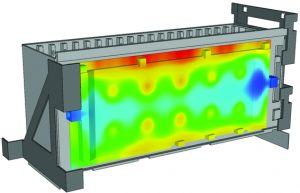

The designers redesigned one of the cold plates as its initial design would not have provided enough cooling to be highly reliable in an aerospace environment.

The cold plate design also had to account for pressure drop requirements.

Thermal/computational fluid dynamics (CFD) analysis using the software allowed Ten Tech to understand the flow and focus of the design to maximise cooling and minimise pressure drop.

The designers created a multi-fluid model of the cold plate involving free convection and liquid cooling and optimised the cooling channels to obtain a good compromise between heat dissipation and pressure drop through the cold plate.

For the liquid cooling of the system a larger chassis included more than 25 high-power single-board computers and five cold plates of various complexity.

Ten Tech had to ensure that the entire chassis was properly cooled, the liquid loop would function correctly and each single-board computer would be within its temperature requirements.

This was a big model, with the added complexity of being multi-fluid with liquid-cooling cavities, and in total encompassed around 40 million simulation grid cells.

Thermal simulation tool

However, by using a dedicated thermal simulation tool Ten Tech was able to shorten solve times by 50% compared to general purpose CFD tools. This also meant that the designers were able to easily simulate several different mission scenarios, corresponding to different altitude, ambient temperature and liquid cooling pump inlet temperature and pressure permutations.

A final design was delivered to the customer in a little over three weeks, well under the original six-week estimate, with extra information provided to improve the design for high reliability.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News