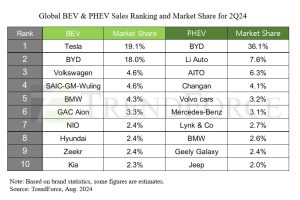

Figure 1: IMU sensors rely on gravity and the physics of motion are not affected by harsh environmental conditions and physical obstructions and will continue to operate

Inertial measurement unit (IMU) sensors may not attract the same amount of attention as other sensors, such as lidar, radar and cameras, but in many ways IMUs are the critical safety sensor component required for the successful operation of the Level 4 and Level 5 autonomous vehicles that will be appearing on roads within the next decade.

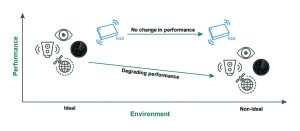

Figure 2: Three axes of movement (forward and backward, left and right, and up and down) as well as three axes of rotation (roll, pitch and yaw) make up the six degrees of freedom

The future of automobiles is autonomy: vehicles that can safely and accurately drive themselves without a human steering and controlling their operation. There are many predictions regarding when truly autonomous cars will become a reality.

While the industry waits for true vehicle autonomy, many of today’s vehicles are equipped with a variety of advanced driver assistance systems (ADAS), such as lane departure warnings, assisted parking and automatic braking. Although very useful, they are considered an SAE (Society of Automotive Engineers) Autonomy Level of just 1 or 2, which means that they still require driver engagement 100% of the time.

The big question is: when will the industry achieve the technological leap to Level 5, fully autonomous vehicles that require no driver interaction?

The industry is still several years away from this technology becoming widely accepted and adopted into any type of vehicle because the critical challenge is ensuring safety.

Full autonomy in vehicles

To achieve full autonomy requires absolute confidence that a vehicle will continue to safely and accurately operate in any type of weather or road conditions and that it will avoid significant injury to passengers, pedestrians or property.

This would require building in a vehicle guidance and navigation technology that can ensure the vehicle will operate safely if and when vehicle perception sensors such as lidar, radar, or cameras fail or there is an intermittent disruption in GNSS satellite signals due to weather, terrain or environment.

This vehicle sensing technology is the inertial measurement unit sensor. Perception sensors are based on gravity and the laws of physics rather than external conditions. If perception sensors fail because of weather, the IMU sensor can continue to send data to the vehicle for it to safely maintain its course until it can come to a secure stop or the other navigation systems come back to life. By eliminating data interruption and increasing operational safety, the IMU will expedite the reality of Level 5, that is, fully autonomous driving.

Figure 1 shows IMU sensors rely on gravity and the physics of motion. Unlike cameras, radar, lidar and other perception sensors, as well as steering systems based on GNSS signals from satellites, IMU-based guidance systems are not affected by harsh environmental conditions and physical obstructions such as tunnels and foliage, and will continue to operate.

IMU sensors in autonomous vehicle.

Most IMU sensors are composed of two sets of sensors, accelerometer and gyroscope sensors. The accelerometer sensors measure linear acceleration in three orthogonal axes. Integrating acceleration over time will provide velocity and integrating velocity over time will change in position.

Figure 3: IMU sensors provide safety, accuracy and reliability for a variety of applications including autonomous vehicles

The gyroscope sensors measure the angular rate of three orthogonal axes. Integrating the angular rate along the three axes over time will generate change in roll, pitch and yaw, which is the change in attitude of an object.

An IMU module with gyroscopic and accelerometer sensors can provide measurement over six degrees of freedom (6-DOF).

Some IMUs also include a magnetometer. An accelerometer can be used to successfully calculate roll and pitch values with respect to Earth’s gravitational force, and correct gyroscope drift. It cannot be used to detect absolute heading (yaw) because the change of yaw is orthogonal to the gravity vector. A magnetometer measures the magnetic field strength in three dimensions. Using the Earth’s magnetic field, it can help to determine heading (that is, yaw) as well as the roll and pitch of the object.

Integrating a magnetometer in the IMU can help with detection of the initial heading of an object and correct integration errors of the yaw gyroscope in the sensor fusion algorithm.

IMU variation

Bis instability is one of the most critical performance parameters of the gyroscope. It is a direct measure of how much the gyroscope drifts over time. The rate output of the gyroscope is integrated to calculate change in angles (roll, pitch and yaw), any error associated with drifts results in accumulated error in relative angles. These angular errors translate into position errors over time. For automotive applications a high performance IMU is a necessary component for the autonomous vehicle to achieve high accuracy positioning

In a triple redundant IMU, three IMUs are used to construct a triple-redundant sensor architecture that provides additional levels of reliability and accuracy. If any sensors are not accurately functioning, the system can be programmed to recognise the defective sensor data and will not utilise it. The defective sensor output or errant dataset will be ignored or de-rated in importance. This architecture ensures the reliability of the system and simultaneously improves the performance.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News