Except, it is seldom publicised, that it is only biodegradeable in industrial-scale high temperature processes, and will last of years in the open environment.

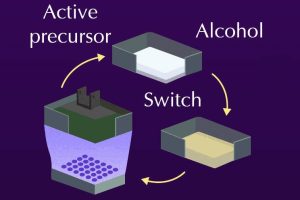

Now researchers at the Toulouse Biotechnology Institute have engineered a designer enzyme – hyperthermostable PLA hydrolase – and a technique to mix it into PLA, to speed up post-use de-polymerisation 80 times.

The resulting polymer, which has only 0.02% by weight of the enzyme, will still biodegrated in industrial composters, but is also compatible with home composting, and the anaerobic digesters used to produce methane.

“The enzymated material is proven to disintegrate and biodegrade at a much faster rate than the 26 weeks required for certification for use in home composting, and also helps produce more biomethane,” according to the Institute.

It can also be stored without self-destructing.

“The enzymated material remains intact during long-term storage, and its degradation will only be activated when it is transferred under composting or methanisation conditions,” said the Institute, “thus ensuring its compatibility with commercial PLA-based applications such as flexible packaging or short-lived items such as food containers.”

Unfortunately

So far, without de-activating too much of the enzyme, the material can only made into products using processes up to 170°C, which is too low for most 3d printing techniques.

PLA is the most commonly used material for 3d printing dimensional prototypes. It is easy to print, rigid and strong, but its low softening temperature and brittle nature preclude it from most final-product use.

The work is covered in the Natue paper ‘An engineered enzyme embedded into PLA to make self-biodegradable plastic‘.

In 2020 the Institute revealed that it had created an enzyme that bio-degrated the high-performance polymer PET.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News