Researchers at the Dalian Institute of Chemical Physics have found a way to deposit micro-supercapacitors consistently on surfaces such as silicon as a way to add energy storage directly to ICs.

Researchers at the Dalian Institute of Chemical Physics have found a way to deposit micro-supercapacitors consistently on surfaces such as silicon as a way to add energy storage directly to ICs.

This is not the first time that supercapacitors have been deposited on such substrates, but the team claims to have combined unpresidented cell density, electrochemical performance and cell-to-cell consistency – the latter important if series-connected cells are to have a long charge-discharge cycle life.

The basic structure is planar, with capacitance developed between interdigitated electrodes on the same flat surface.

The basic structure is planar, with capacitance developed between interdigitated electrodes on the same flat surface.

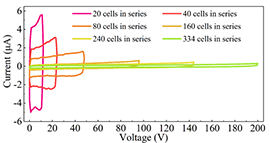

Capacitors are formed side-by-side and electrically-isolated, allowing them to be deposited in arrays and then linked by conductors into series or parallel combinations.

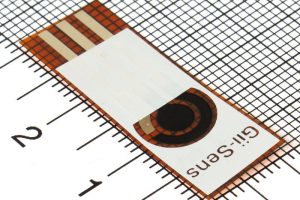

The technology demonstrator consisted of 400 cells on deposited on a 3.5 x 4.1cm rigid substrate (28 cells/cm2) that achieved an output voltage of 75.6V/cm2 and a volumetric density of 9.8mWh/cm3. Capacitance was 4.1mF/cm2 and 457F/cm3.

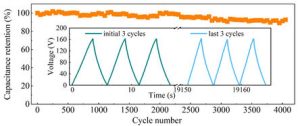

92% if initial capacity was retained after 4,000 charge-discharge cycles (60 series cells charged to 162V at 2.7μA).

92% if initial capacity was retained after 4,000 charge-discharge cycles (60 series cells charged to 162V at 2.7μA).

A gelled electrolyte (polyvinyl alcohol + sulphuric acid) was deposited by 3D printing through a 210μm bore needle moving at 4mm/s to complete the cells. Being a gel, no walls were needed to restrain the electrolyte from shorting to adjacent cells despite their proximity. Neither dot printing nor line-segment printing could be persuaded to achieve the required printing accuracy.

A working 340 cell array was also printed on a flexible PET polymer substrate.

The work is published as ‘Monolithic integrated micro-supercapacitors with ultra-high systemic volumetric performance and areal output voltage ‘ in National Science Review. The complete paper can be read without payment.

Dalian Institute of Chemical Physics worked with the Shenzhen Institute of Advanced Technology.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News