Low down on DC-DCsRichard Wilson

Processor and logic manufacturers continue to place power supply design under a lot ofpressure, especially where low voltage devices are concerned. With supply voltages forleading devices such as microprocessors dropping sub-1.0V, maintaining efficiency of powersupplies is tremendously difficult.

As supply voltages approach 0.6V they are getting dangerously close to the voltage dropacross the diodes typically used for rectifying the converter outputs. Below 1.0Vachieving power efficiencies above 75 per cent becomes a big design issue. And low powerefficiency equates to more cost and size.

Thistrend towards lower voltage is forcing power converter designers to use more exotictopologies and Mosfets for their low voltage drop. Many designs now use synchronousrectification to maintain power efficiency at lower voltages.

Artesyn Technologies has a half-brick 100W DC-DC converter module for poweringlow-voltage semiconductor devices. Available with single 5.0V (20A), 3.3V or 1.8V (30A)outputs, the EXB100 converter is a synchronous rectifier heatsink-less design. Each ofthese models features a voltage trim facility with a range that enables the output to beadjusted between 60 per cent and 110 per cent of its nominal value.

This means that the 1.8V model, for example, can be trimmed down to just 1.08V, whiledelivering its full 30A rated output at this voltage level.

The 3.3V model, for example, has an efficiency of 90.5 per cent, which typically meansthat with just 1m/s of forced air-cooling, it can deliver its full 30A output at ambienttemperatures of up to 50?C.

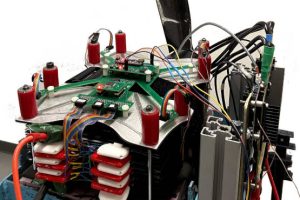

Also in the 90 per cent efficiency league is a quarter brick 75W dual output DC-DCconverter from C&D Technologies (pictured bottom left). It is specified to achieve a90 per cent efficiency rating on 10 per cent trimmable 3.3V and 5.0V outputs.

Like with most converters the aim has been to reduce external component count byintegrating non-latching protection against input undervoltage, input overvoltage, outputovervoltage and over temperature into the VSX75MD35 converter. It also features continuousshort circuit protection, input filtering and a remote on/off capability.

SynQor is another synchronous rectification specialist and its PowerQor Tera series ofhalf-brick DC-DC converters now includes a 1.2V output module.

Typical efficiency numbers for the 1.2V module are 88 per cent at half-load (30A) and84 per cent at full load (60A). The company said it is also developing modules at 1.2V andlower.

Package design including ceramic substrates and copper tracks can also be used toimprove efficiency. Thick film is still used for manufacturing passive components, butcurrent carrying tracks are metal, which reduces resistivity.

Some companies design on ceramic substrates using thick films for interconnect betweencomponents. But thick films have a relatively high resistance.

Higher current inevitably leads to the issue of heat dissipation and hence theimportance of device efficiency.

One of the important things with a converter is the temperature of the FETs. Somesuppliers tackle this by being clever in the way they bond the FET die directly to analloy baseplate to improve the efficiency of heat conduction.

The power/size trade-off is everywhere in converter design. For example, considerswitching frequency. With higher frequencies the size of key components like transformersis reduced. However, switching currents at higher frequencies increases losses and reducespower efficiency.

Vicor’s approach to this is a converter design, which it patented some time ago,that switches at zero-current giving less radiated and conducted noise.

It is sometimes referred to as a soft-switched technology where the FETs only switchwhen they have zero-current flowing, thereby reducing parasitics and losses.

The result is small package size and higher efficiency. For example, Vicor’s rangeof PowerStick board mounted DC-DC converters, which measure 2.28 x 0.5 x 0.l35in, have aspecified power conversion density of 188W/in3. The firm’s intention was to doublethe power density of standard telecoms DC-DC converters. “Specifically, ourconverters deliver twice the power of 30-40W SIP-type packages and double the powerdensity of larger quarter brick modules,” said Andrew Hilbert, product marketingdirector at Vicor.

The range will deliver up to 75W per module and up to 900W in fault tolerant arrays.

To achieve the peak power density the module comes with an optional wraparound aluminumbody to provide cooling.

Advanced Power Conversion also uses soft-switching techniques in its latest 500W fullbrick DC-DC converter which claims a best in class full load efficiency of over 90 percent.

Behind the design is a full H bridge transformer with soft switching andcurrent-doubler rectifier, with integrated magnetics.

Power One uses a patented combination of resonant switching techniques and synchronousrectifiers in is ranges of DC-DC converters. There is a 30A quarter brick and even aneighth-sized brick. The 15A E2S converter (pictured below) is surface mountable with an8.5mm profile and has outputs down to 1.0V.

“There is a real drive in the market now for pushing the voltage down,”points out Steve Allen, v-p sales and marketing at Power One.

European designs may still favour 3.3V typically, but according to Allen there is now amove in the US in particular to 2.5V and 1.8V designs, and it is only a matter of timebefore European designs follow suit.

According to Allen, converter size is the other big technology challenge which PowerOne has tackled with its low profile (8.5mm) E2S 1/8-brick.

Competition in the supply of high power density (measured in W/in3) DC-DC converters isfierce, with suppliers pushing the physical limits of power conversion.

For example, Lambda’s PAF range of full-brick converters now offers a 600W module,the PAF60048. Power density is a “competitive” 6.63W/cm3 (109W/in3).

To compare, Advanced Power Conversion’s APC500 full brick (116.8mm x 61.0mm x12.7mm) converter is specified with a power density of 5.53W/cm3 (90W/in3).

The APC500 has an operating frequency of 300kHz which can be synch ronised to anexternal clock in the interest of design of noise sensitive circuits.

Tyco Electronics Power Systems’ JHW050xx series dual output 50W DC-DC converter isspecified to operate at an efficiency of 87 per cent when powering 3.3V/1.5V outputs.

A feature of the JHW050xx series is the input/output voltage trimming by ?5%, whilealso allowing the core voltage to be set as low as 0.8V. It also has a power tradingarchitecture, which allows current to be drawn from both outputs in any combination.

One problem designers have is that power requirements of processor systems can varyover time and throughout the period of operation. It is the DC-DC converter which mustallow for pre-defined changes in the system load requirements. This sequencing of thepower output is carried out by a separate control circuit.

Tyco incorporate a sequencing feature with a separate control pin in its JHW050xx rangeto aid the design of control circuits.

“Typically, designers working on advanced communications devices are uncertainabout how much power their chips will require and how this power will be shared betweenthe I/O and core,” said Kirit Wadhia, sales and marketing director at TycoElectronics Power Systems.

It is a de facto requirement of all converters these days the output voltage rangeneeds to be wide from 12V down to sub-1.0V to meet the needs of lower voltage devices. Forexample, Artesyn Technologies’ 100W half-brick will deliver its 30A output at 1.08V.

International Rectifier also offers a power module which is aimed at a niche betweendiscrete component DC-DC converters and brick modules. Overall efficiency can be as highas 97 per cent (3.3Vin, 2.5Vout at 4A), and stays around 90 per cent for most line-loadcombinations.

The iP1001 includes all necessary semiconductors to make a 20A non-isolated DC-DCconverter with an output between 0.925 and 3.3V. All the designer has to add are input andoutput capacitors and an inductor.

Output voltage is set by an internal D to A converter whose inputs can be hard-wired ormanipulated on-the-fly.

Ericsson Microelectronics’ latest half-brick DC-DC power converter, the PKL 4118Adelivers 100A at 1.8V at a power density of 62W/in3 (3.78W/cm3). This 36-75V input moduleoffers an 83 per cent efficiency at full load.

Last year Astec Power introduced its first 80A half brick DC-DC converter. Thequarter-size AK45C provides up to 20A and 100W of output power at what the supplierspecifies as up to 89 to 90 per cent efficiency.

Ericsson’s PKL 4000 series half-brick DC-DC power module has a 90 per centefficiency at 310W.

www.irf.com

www.apcuk.com

www.artesyn.com

www.cdtechno.com

www.ericsson.com

www.power.tycoelectronics.com

www.lambda-gb.com

www.vcr.com

www.synqor.com

www.power-one.com

www.astec.com

By Staff Posted on 7th July 2004 | Modified on 7th July 2004

Tagged with: battery diode rectifier electronics design Electronics Power lithium ion batteries mosfet Power Supply Information superconductor voltage converter voltage regulator

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News