Liion roars …at a priceSteve Bush

Lithium ion batteries are in all the best phones and camcorders, so why are they noteverywhere, in every bit of portable test equipment for instance? A simple answer is cost.Liion batteries are more expensive to buy than NiCd or NiMH cells.

“Lithium batteries are lighter than nickel cadmium or nickel metal hydride,”says Robin Cloke, MD of GP Batteries in the UK. “They are also more expensive and notmuch different from hydride batteries in power per unit volume. Lithium ion is best whenweight is the first consideration and cost is the second.”

There is another reason Liion cells are not all-pervasive. The cells are much moretouchy than their nickel cousins.

National’s LM3622 is a constant voltage, constant current controller for single and dual cell Liion packs.

Whereas a nickel cadmium cell seldom suffers more than reduced cycle life when abusedby the clumsiest of unregulated chargers, a lithium cell can bite back hard if mistreated.

The recall of one famous-name laptop after a series of battery fires shows even firmsthat spend a lot of money on development can get it wrong.

This does not mean Liion cells cannot safely be used. It means that designers cannotcut corners when incorporating them.

“You have to have in place a quality system that ensures, even if a single pointfailure occurs, it will not damage the system,” warns Francisco Mercado, charger chipdesigner at National Semiconductor.

To make this valuable technology safe, a two-part strategy has developed.

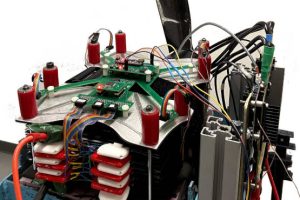

Firstly, any charger has to be electronically regulated with a strict voltage limit, acurrent limit and charge termination control.

Secondly, closely-coupled to any cell or battery is a protection circuit which preventsover-voltage during charge, over-current in discharge, over-current in charge and balancescell voltage in batteries with three or more cells – and sometimes with two. Thisprotection is electronic, further backed-up by some form of fuse. Recently a new back-stopsafety device has been created especially for Liion battery packs. It consists of athermal fuse to protect from excessive current, combined with a heating element whichmelts the fuse if excessive voltage is present. Sony’s SFC series are examples.

The protection circuit is regarded as essential, and is the reason naked lithium ioncells are difficult to obtain.

“We don’t sell batteries without protection,” says GP Batteries’Cloke. Instead, his company stocks protected standard Liion packs and turns around customassemblies in two to three weeks.

Cloke’s view is that once a pack has protection in, there is less to go wronglater. “They only have to design a constant voltage current-limited charger,” hesays.

The charger is still not trivial, but is made easier by specialist chips from mostanalogue semiconductor vendors. Some of these are aimed at standalone applications, whileothers are application specific and can include much of the power management circuitryrequired by, say, a mobile phone.

The charge voltage must be accurately regulated, to better than one per cent in mostcases. “Charge voltage depends on anode material,” says Dave Heacock, managerfor portable power products at Texas instruments. “Coke-based cells are a little lessexpensive and need 4.1V, graphite anodes give a flatter discharge curve and require4.2V.”

This voltage does not have to be compensated for cell temperature, although makersspecify a temperature range outside which cells should not be charged.

Charge current has to be limited early in the charge cycle to prevent damage, andmaximum current is specified by the cell maker. Some allow current equal to its capacity -2A for a 2Ah cell, for example. To minimise charger dissipation, switching type regulatorsare normally employed above 1A.

Once the charge cycle enters constant voltage mode, current can be suppliedcontinuously, or in pulses. Pulses are used by a class of low dissipation chargers thatincorporate a simple on-off transistor and rely on current limiting in an associatedplug-in wall transformer.

Most agree this pulsed approach is fine provided each pulse ends before cell voltageexceeds 4.1 or 4.2V, depending on the cell. However, fixed length pulses, which may pushterminal voltage above the critical voltage, can diminish cell life and cause otherover-charge maladies.

Charging has to be terminated. Although there is some disagreement, most of the batteryindustry says Liion cells cannot be permanently left on charge, whatever the current.

Current is commonly removed when, at 4.1 or 4.2V, it naturally drops below one tenth ofits capacity – 200mA in the case of a 2Ah cell – a point known as the C/10 rate. A safetytimer should be added to terminate charging if a cell fault means current never drops tothe chosen threshold.

Should it become necessary to design protection circuitry for a battery pack, chips areavailable, again from most analogue chip vendors.

Designing-in protection circuitry should only be undertaken after fully understandingthe chosen cell’s characteristics and the consequences of component failure in theprotection circuit.

Example of lithium ion cell specifications can be found at: www.sony.co.jp/en/Products/BAT/ION/Catalog-e.pdf http://www.mbi.panasonic.co.jp/oembatteries/english/index.html

By Staff Posted on 7th July 2004 | Modified on 7th July 2004

Tagged with: battery diode rectifier electronics design Electronics Power lithium ion batteries mosfet Power Supply Information superconductor voltage converter voltage regulator

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News