G9KB-E is based on the earlier G9KB family, and is the same size and weight (37 x 50mm footprint and 50mm tall), but can switch higher power, up to maximums of 800Vdc or 100A.

Envisaged use is normally to switch a circuit at low current, but to have the capacity to break high current in emergency and fault conditions.

Estimated lifetimes are:

- 600Vdc 100A – 100 operations

- 500Vdc 100A – 300 operations

- 800Vdc 50A – 10 operations

- 800Vdc 18A – 6,000 operations

- 800Vdc 100A – not permitted

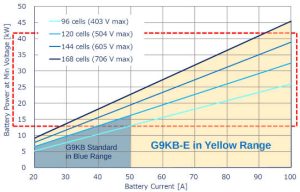

Omron’s suggested operating range (red rectangle)

Omron’s suggested operating range (red rectangle)

It can cope with bi-directional DC switching, allowing it to replace a pair of uni-direction relays, and includes arc quenching to turn off high-power dc flows. “3D arc simulation has been used to visualise the arc phenomenon and optimize the arc cut-off process, resulting in a more compact design with improved safety,” claimed Omron, which added: “It features no hydrogen gas for improved safety.”

Contact resistance is 5mΩ, and there are two coil options: 12V (51Ω) or 24V (206Ω).

Activation is always a two-stage process, with an initial 100ms to 3s pulse at 100 – 110% rated voltage (~2.8-3.4W), followed by holding at 45-60% (0.57-1.1W). 100% voltage cannot be applied continuously.

Dielectric ratings are: 5kVac (50/60Hz 1min) between coil and contacts (10kV (1.2×50μs) surge), and 2.5kVac (50/60Hz 1min) across the 3.6mm open contacts.

Certification is to UL60947-4-1, EN 61810-10 (TUV), andGB/T 21711.1 ( CQC).

As with the standard G9KB, G9KB-E can only be mounted in certain orientations with respect to gravity – see the data sheet – and its malfunction shock resistance differs among the acceptable orientations.

Find the G9KB-E (and G9KB), product page here and the data sheet here

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News