So much like a child’s transfer is it, that it is made on the same type of substrate and applied the same way: wet it, stick it, and peel off the backing paper.

The OLED starts life as a sheet of commercial ‘tattoo paper’ – this is already a laminate of a smooth-surfaced paper called glassine that is coated with a water soluble starchy layer, then topped with a water-resistant layer of ethylcellulose – the latter of which is usually printed on to make the tattoo image.

In use, water soaks through the paper, dissolves the soluble layer into a slippery sludge, allowing the ethylcellulose layer to be left on skin with its image.

In the University College case, instead of a printed image, a PMMA (‘acrylic’ – poly(methyl methacrylate)) barrier layer is first applied to the tattoo paper by spin coating to protect the paper from solvents used later in the process.

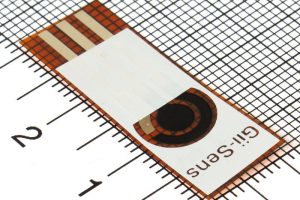

Next comes a transparent bottom electrode that doubles as a hole injection layer (faint lines in the photo), made by ink jet printing the polymer PEDOT:PSS.

A green-emitting polymer called F8BT (yellow) is spin-coated over the bottom electrodes, then the structure is finished with evaporated aluminium top electrodes (dark lines).

A green-emitting polymer called F8BT (yellow) is spin-coated over the bottom electrodes, then the structure is finished with evaporated aluminium top electrodes (dark lines).

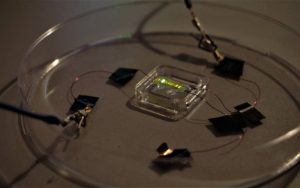

The inverted structure is needed because the transfer process turns the stack up-side-down, putting the aluminium layer next to the skin – although the researchers point out the there is no reason it could not be constructed the other way up to emit light into the skin, for medical reasons for example.

“In healthcare they could emit light when there is a change in a patient’s condition – or, if the tattoo was turned the other way into the skin, they could potentially be combined with light-sensitive therapies to target cancer cells, for instance,” according to UCL professor Franco Cacialli. “The tattooable OLEDs that we have demonstrated can be made at scale and very cheaply. They can be combined with other forms of tattoo electronics for a wide range of possible uses. These could be for fashion – for instance, providing glowing tattoos and light-emitting fingernails. In sports, they could be combined with a sweat sensor to signal dehydration.”

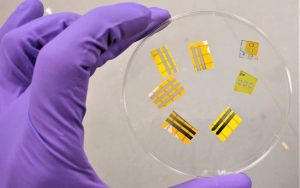

To extend this proof-of-concept, encapsulation to prolong life is the next step, then adding a power source

UCL worked with Istituto Italiano di Tecnologia (‘IIT’ Italian Institute of Technology)

The work is published as ‘Ultrathin, ultra‐conformable, and free‐standing tattooable organic light‐emitting diodes’ in Advanced Electronic materials – abstract only available without payment.

Images: Barsotti / Italian Institute of Technology

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News