The process, known as chemical vaporisation machining (CVM), involves a chemical reaction between neutral radicals in the plasma and the surface of the workpiece.

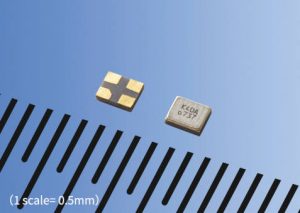

It produces crystal wafers with nanometre-level thickness uniformity without damaging the wafer surface, allowing mass production of quartz wafers with reduced frequency dispersion for use in compact quartz resonators.

These are so far used in phones, wearables, hearing aids and medical devices, although “this technology will also allow Kyocera to develop a variety of products in the future, including: low-frequency oscillators for automotive electronics, high-frequency oscillators for communications base stations, and miniaturised components for driver assistance systems,” said the company.

The award was the 2021 ‘Science and technology award (development category)’ from Japan’s Ministry of Education, Culture, Sports, Science, and Technology, which recognises individuals and enterprises that have made outstanding achievements in research and development, or inventions, that improve the social economy and contribute to a higher quality of life.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News