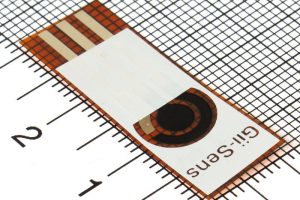

There are two cardiac monitors, a mini version with three electrodes for short-term monitoring, and one with six electrodes for longer periods.

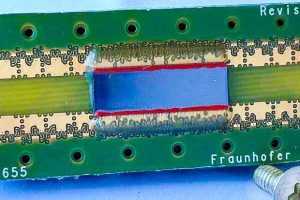

“A completely new approach to integration was developed in this work,” according to Wurth. “It was based on a stretchable printed circuit board made of TPU [thermoplastic polyurethane]. It was possible to make this using standard PCB production techniques, which brought the advantages of conventional PCB technology, such as assembly using pick-and-place machines.”

Electrodes for body contacts were printed directly onto the PCB, and it was robust enough to have a system-in-package module mounted in it.

“The stretchable PCB provided a very pliable, biocompatible substrate, said Wurth, which partnered with Fraunhofer IZM, Fraunhofer ENAS, IMEC and Precordior.

This was part of the wider three year €34m European Applause project: ‘Advanced packaging for photonics, optics, and electronics for low-cost manufacturing in Europe’.

This has 31 partners with the overall aim of strengthening the European medical sector semiconductor value chain by developing tools, methods, and processes for volume production.

Continuing on the cardiac theme, Applause included a ‘minimally invasive’ cardiac implant in the form of a catheter was equipped with accelerometers to measure heart contractions. Its novel ultra-flexible and rigid-flexible stack-ups were designed by Wurth and Osypka.

Lastly for Wurth, it contributed hybrid panel-level PCB packaging to an Applause project that created low-cost thermal imaging systems – that included wire bonding and the encapsulation of large optical chips.

“Through work on the Applause project, we have taken significant steps forward in the development of complete medical systems and, in particular, close-to-body applications,” said Würth’s head of research Alina Schreivogel. “This is down to the synergies and collaboration between the partners within the consortium. Discussions are currently being held on moving on to industrial production.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News