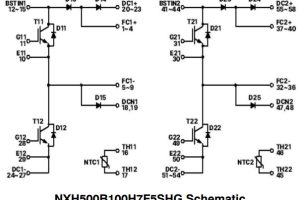

International Rectifier, launched its ‘Gen 8’ IGBTs at Electronica. Gen 8 takes IR into the industrial motor drive market from being primarily a supplier of IGBTs to the domestic appliance market.

“IR’s Gen8 IGBT platform offers a superior technology targeting industrial applications. With best-in-class Vce(on), robustness and excellent switching characteristics, this IGBT platform has been specifically tailored to achieve the demanding challenges of the industrial market,” says IR’s Llewellyn Vaughan-Edmunds.

“When Oleg (Khaykia) became CEO he decided to focus first on MOSfets – and now we’re No.1 in MOSfets – then he decided to focus on IGBTs,” says Vaughan-Edmunds.

Khakia took over in 2008 and the push on IGBTs started last year. “IGBTs can either be fast or have low conduction losses, IR has gone for low conduction losses,” says Vaughan-Edmunds.

Gen 8 devices are made on 140 micron thick wafers because, says Vaughan-Edmunds: “The thinner the substrate the more efficient the heat dissipation. Efficiency is everything, that’s what it’s all about.”

Gen 9 will use wafers which are 60 micron thick..

IR’s stated goal is to achieve 100% inverterisation of all electric motors for a more efficient use of electric energy.

Gen 8 offers softer turn-off characteristics ideal for motor drive applications, minimizing dv/dt to reduce EMI, and over-voltage, increasing reliability and ruggedness.

A narrow distribution of parameters offers excellent current sharing when paralleling multiple IGBTs in high-current power modules. The thin wafer technology delivers improved thermal resistance and maximum junction temperature up to 175°C.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News