In recent years, capacitive touch technology has increasingly become adopted in electronic applications to replace traditional mechanical switches.

One of the advantages with capacitive controls is that they can be used through a range of materials.

Each capacitive key takes the form of an electrode which is printed onto a substrate material which is then attached to the back of a front panel.

The substrate can be made of any insulator, PCB materials such as FR4 are ideal as are acrylics and glass.

Electrodes can be made of any conductive material, the lower the resistivity, the better. Typical materials include copper, silver ink and ITO. Carbon can also be used – in fact, an electrode can be drawn on a piece of paper and used effectively as a touch button.

Electrodes can be any size or shape, as long as they cover a larger surface area than the target. Something equivalent to 8mm diameter circle is usually recommended for a touch button as a finger is roughly 6mm-8mm in diameter. Electrodes can also be solid or meshed.

The front panels tend to be glass in the case of cooktops – plexiglas, polycarbonate and PMMA are common materials used in the casing of consumer products.

Capacitive touch technology can also be used in proximity sensing applications. This type of functionality can be used in hidden-until-lit keypads, saving energy by only illuminating the keypad when a nearby hand is detected. Another application is for use in mobile phones, to disable a touchscreen or other touch keys during a call.

Alternative proximity sensing technologies include the use infra red to detect if an object is nearby. Careful PCB design is required for such systems including relative positioning of the emitting infrared LED and the receiver.

Adding infra-red sensing will also change the mechanical design of a product, although the surface may be smooth, glass must be used over the sensor and the refractive index must be selected specially to guarantee good performance.

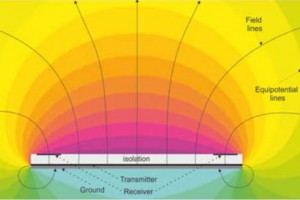

A capacitive proximity sensor is just like a standard capacitive touch button but made more sensitive to detect an approaching target before it contacts the front panel surface. Sensitivity can be increased by making the capacitive electrode larger and the sensing capacitor value higher.

Typically the proximity sensor is an electrode made of copper that is on the PCB. Care does need to be taken in the design because if there is metal in the casing this can have a restricting effect on the proximity. However, unlike infra-red proximity sensing, no changes are required to the mechanics of the design.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News