Renesas is aiming its next generation of IGBTs at electric vehicle inverters, and is making them on 300mm wafers.

Renesas is aiming its next generation of IGBTs at electric vehicle inverters, and is making them on 300mm wafers.

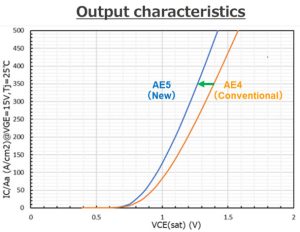

Behind them it its new ‘AE5’ process. “The silicon based process achieves a 10% reduction in power losses compared to the current-generation AE4 products,” said Renesas, “In addition, the new products are approximately 10% smaller while optimally balancing low power loss and robustness trade offs.”

A few device details have been released:

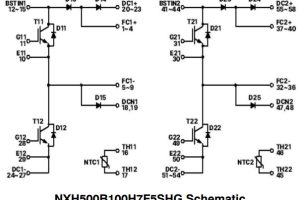

There will be four AE5 IGBTs, according to Renesas, all sold in die form and aimed at 400-800V inverters: a pair of 750V transistors rated at 220A or 300A, and a pair of 1.2kV transistors rated at 150A or 200A.

The 750V 300A part (RBN300N75A5JWS) has a 100mm2 die.

Operation will be with junctions across -40 to +175°C, and collector-emitter saturation voltage will be 1.3V (see graph).

RBSOA (reverse bias safe operating area) will include 600A pulses with the junction at 175°C, and they will withstand a 4µs short-circuit from 400V.

Compared with its earlier devices, threshold voltage variation between individual IGBTs has been tightened from ±1.0V (typ) to ±0.5V to increase stability when devices are used in parallel inside power modules.

There will also be a “50% reduction in the temperature dependence of gate resistance. This minimises switching losses at high temperatures, spike voltage at low temperatures and short circuit withstand time”, said Renesas. Overall, in inverters, the new parts will improve “power efficiency by up to 6% compared to the current AE4 process at the same current density”.

Samples of the 750V 300A IGBT, and a matching 750V 300A AE5 fast-recovery diode (RBC300A75F3JWS) are available.

Mass production of AE5-based IGBTs is scheduled to start in the first half of 2023 on Renesas’ Japanese 200 and 300mm wafer lines in Naka, then to ramp-up on its new 300mm power semiconductor line in Kofu in the first half of 2024.

For development, there is the ‘xEV inverter’ hardware kit, which combines an IGBT, fast recovery diode, gate driver IC, microcontroller and power management IC. Along with this comes a motor parameter calibration tool, an application model and sample software for controlling the motor.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News