Loctite has created a silicone form-in-place gasket material for automotive electronic enclosures. SI 5972FC is a one-part RTV (room temperature vulcanising) liquid-then-elastomer “with adhesion to a range of metal and plastic surfaces, specifically designed to pass OEM leak or blow-out pressure tests immediately after assembly”, according to the company. “By avoiding the need for curing ovens, Loctite SI 5972FC also ...

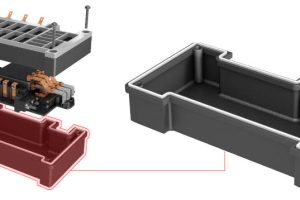

Emech & Enclosures

The latest Electronics Weekly product news on emech and enclosures.

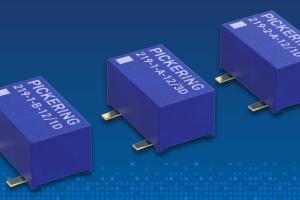

Pickering adds high voltage surface mount reed relays

Pickering Electronics, has announced its first high voltage surface mount reed relays known as the Series 219. Available in multiple package types (of the same size, but with differing pin positions), these reed relays can switch up to 1000V in 1 Form A (SPST), 2 Form A (DPST), and 1 Form B (SPNC) contact configurations; switch stand-off is up to ...

Ultrasonic micromachine puts bass into earbuds

XMems Labs has revealed a mems-based loudspeaker that uses ultrasonics to reproduce bass notes. Branded ‘Cypress’, the company describes it as “full-range” and said that it “achieves >140dB low frequency SPL [sound pressure level] enabling a no-compromise replacement for coil speakers in noise-cancelling earbuds”. In an earbud, there would be three parts: a conventional wireless earbud receiver IC, a custom ...

Productronica: high-voltage SMD reed relays

Pickering Electronics will introduce a series of surface-mount >1kV reed relays at Productronica in Munich next week. Series 219 reed relays “can effortlessly switch up to 1kV, and are the only surface mount high voltage relays available in the market in 2 Form A and 1 Form B packages”, according to the company. Some details are available now: stand-off is ...

Buzzers automatically make IEC 60601-1-8 medical alarm sounds

CUI Devices has announced a line of medical buzzers compliant with IEC 60601-1-8 alarm signal requirements. There are four CPIM-4410-80x buzzers, with a letter replacing the ‘x’ depending on function: C for the cardiovascular tone, T for the general tone, V for the ventilation tone and Y for the oxygen tone. Each has a stand-by (silent) mode and three alarm ...

600V opto-isolated mosfet is under 5mm long

After announcing 60V opto-mosfet relays last week, this week Panasonic has revealed a 600V type in a 2.65 x 4.45 x1.8mm package. AQY206GV’s 8Ω mosfet (15Ωmax) will switch 600V, and 150mA (450mA pulsed), with a maximum dissipation of 350mW. Its SSOP package is rated for 1,500Vrms isolation, and the whole device will work up to +105°C ambient. Maximuturn on and ...

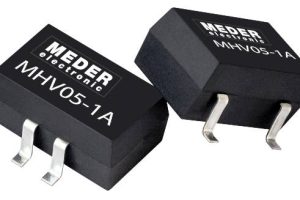

Power reed relays are surface-mount, or have axial leads for 10TΩ isolation

Standex Electronics has announced two series of high-voltage power reed relays, one surface-mount and one axially leaded. MHV series of miniature high voltage reed relays are surface mount and measure 17.2 x 10.5 x 8.5mm. They can switch up to 1kVdc (or ac peak) and withstand a minimum of 3kVdc. “Off-state leakage current is in the nanoampere range, and dielectrics ...

CUI adds a lot of illuminate tactile switches

CUI Devices has introduced dozens of illuminated tactile push button switches, in packages as small as 3.4 x 3.4 x 1.5mm. Colours span blue, green, red, red-blue, red-green, white and yellow, and there are actuator heights from 0.35 to 6.3mm, operating forces from 160 to 300gf, and lives up to 100,000 cycles. “These illuminated tactile switches carry surface mount or ...

Steer-by-wire module for bespoke and low-volume vehicles

Cambridge-based Titan has announced a steer-by-wire system for vehicles “from electric hypercars to automated trucks which has been designed to meet demand from lower-volume manufacturers who need a bespoke system”, it said. The 48V electric motor that operates the steering rack was developed in-house along with the rest of the mechanical system and the control unit. All of it is ...

Ultrasonic lens cleaning brings camera reliability into focus

As advances in autonomy multiply the number of cameras and sensors on vehicles, drones and robots, a purely electrically driven method can help keep them all clean, write Texas Instruments staff members. In the same way a dog instinctively shakes itself clean, ultrasonic lens cleaning technology uses precisely controlled vibrations to self-clean camera lenses when they become dirty or wet. ...

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News