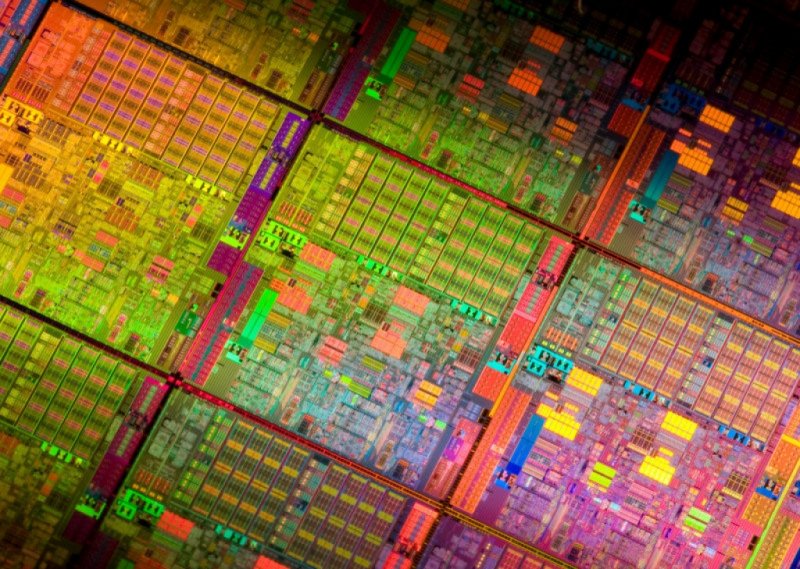

In the Lam study, machine and human participants competed to create a targeted process development recipe at the lowest cost, weighing a variety of factors associated with test batches, metrology and overhead expenses.

The study concluded that while humans excelled in solving challenging and out-of-the-box problems, a hybrid human first, computer last strategy can help address the tedious aspects of process development and, ultimately, speed up process engineering innovation

“Our research showed that while engineering talent remains essential to innovation, process engineering costs can be reduced by 50 percent by integrating AI at the right stage and with the right data,” says Lam vp Rick Gottscho, “the study provides a prescriptive approach for bringing together the best of human-led engineering and the best of what data science and machines offer to create a combination that performs better than either one alone.”

Lam is currently incorporating the key learnings from the study into its development operations.

“By complementing engineering expertise with AI using the human first, computer last approach, the tedious and laborious aspects of design are alleviated for engineers, freeing them up to focus on the creative areas of development and explore innovations that may have been out of reach either due to bandwidth or cost,” said Keren Kanarik, technical managing director of Lam Research, lead author of the research paper and a former process engineer.

The study will be featured in the April 13, 2023 print edition of the journal Nature, and is currently also available on Nature.com.

Media Resources: Visit the Lam Newsroom to download the full study, “Human-machine collaboration for improving semiconductor process development”.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News