It is based on ‘Gaussian mixture models’ – GMMs.

“Neural networks are powerful but have a major drawback: handling unseen data, like defects in a product during manufacturing, is a challenge due to their reliance on existing training data. Entirely novel inputs often get misclassified into existing categories,” according to the company. “Companies cannot collect real-world samples for every anomaly, especially for unanticipated defects. GMMs are clustering techniques that we can use for anomaly detection.”

The software development tool, ‘FOMO-AD’, is designed to create GMM-based detection algorithms for resource-constrained devices like MCUs.

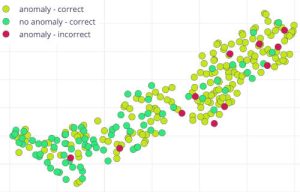

A GMM represents a probability distribution as a mixture of multiple Gaussian (normal) distributions. Each Gaussian component in the mixture represents a cluster of data points with similar characteristics. “Thus, GMMs work using the assumption that the samples within a dataset can be modeled using different Gaussian distributions,” said Edge Impulse.

Anomaly detection using GMM involves identifying data points with low probabilities, it continued. If a data point has a significantly lower probability of being generated by the mixture model compared to most other data points, it is considered an anomaly and a high anomaly score will be output.

“GMM has some overlap with K-means, however, K-means clusters are always circular, spherical or hyperspherical when GMM can model elliptical clusters,” added the company.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News