According to Leti this will allow equipment to perform better than is possible with standard control techniques like PID (proportional integral derivative) feedback.

However, MPC requires complex computing – solving optimisation problems under constraints.

“The control law is based on an optimisation technique that computes the system inputs, taking into account the reference that the system output has to follow, together with the energy that is applied on the system inputs and some constraints that may exist within the system, typically saturation of the system inputs,” said Leti.

So, can it be done?

Leti is giving little away.

“The control community, including academic researchers and process control experts in industry, is trying to make MPC available for these systems by resolving the underlying optimisation problem on a low computational-capability computing platform,” said Leti business development manager Marie-Sophie Masselot. “This short-coming usually leads to sub-optimal performance for the controlled system. Our project with EFI Automotive will take into account specifics to offset the drop in performance, or response time, introduced when solving the model predictive control problem on this low computational-capability computing platform.”

The deal is to transferring MPC knowledge from Leti to EFI, and Leti will develop MPC software tools.

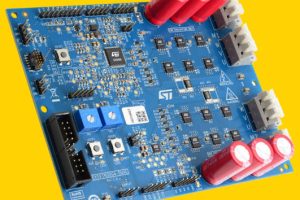

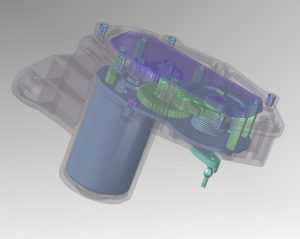

“By combining Leti’s MPC expertise with our know-how in real-time processing on low-computational capability computing units, we expect to improve the response time and reliability of our devices,” said EFI engineer Vincent Liebart – EFI has identified an ‘air loop actuator’ as a typical system that would be improved by MPC (see pictures).

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News