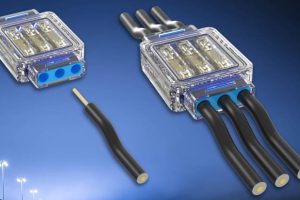

Called 9169-000, they combine insulation displacement contacts for the wire with beryllium copper compression contacts for board edge pattern.

Locating ribs engage with slots on the PCB edge for polarisation against improper insertion, and moulded plastic clips drop into holes in the PCB to improve retention.

“It is possible to establish high-integrity connections and deliver excellent electrical and mechanical performance in harsh-environment automotive, transportation and solid-state lighting, industrial, and consumer electronics applications,” according to the company.

Contacts are on a 2.5mm pitch, and parts with between 2 and 10 contacts are available, with four contact options to terminate solid or stranded wires from 22 to 28AWG.

made from glass-filled PA66 (UL94 V-0) with a choice of eight colours: white, black, orange, green, red, yellow, blue and brown.

PCBs have to be 1.6mm thick, with gold or tin-plated landing pads for the contacts.

The housing is 5mm thick, of which 1mm sits above one side of the board and 2.4mm on the other side.

Glass-filled PA66 (UL94 V-0) is used, with a choice of eight colours: white, black, orange, green, red, yellow, blue and brown.

Ratings are 100Vrms ac or the dc equivalent, then 3A for variants with 2 to 6 contacts (US UL) and 2A for 7 to 10 contacts.

Durability is 10 mating cycles, and operation is across -40 to +130°C.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News