The scheme is called ‘Mouldshare’, and it does what it says on the tin – a single moulding tool is made to manufacture parts for multiple customers.

“In general, setup costs for standard moulded backlights are in the region of £5,000 to 10,000 depending on the design, and a typical MOQ [minimum order quantity] would be around 20,000 units,” according to OMC. “Mouldshare reduces typical setup costs to the £1,000 to £3,500 region, with MOQs as low as 500 pieces.”

For those needing fewer parts, the firm also offers its ‘Profiled’ service where parts are made on CNC machines.

“From a market position perspective, the new series bridges the gap between the Profiled backlight range, which have little or no set up costs and MOQs as low as five pieces, and the standard moulded backlight range,” said the firm.

Key to enabling Mouldshare is a ‘sliding-gate’ injection moulding technique developed by at OMC which allows one moulding cavity in a multi-cavity tool to be used at a time.

No one will have to hang-around while other customers are fund to share a mould tool, OMC commercial director William Heath told Electronics Weekly, although they will still have to wait the standard six-eight week tool creation time and standard production lead-time. “Mouldshare is not about lead-times, it is mostly about set-up costs and MOQs”, he said.

Moulded backlight

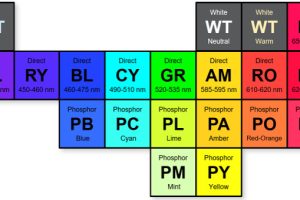

‘Moulded backlight’ is a slight misnomer: the light-guide of the backlight is moulded (or CNC machined), then various reflective layers, phosphor layers and light sources are bonded or clipped into place to make the backlight.

As with OMC’s standard injection-moulded backlights, Mouldshare parts designs can have the firm’s ‘simulated multi-source’ emitting elements and integral dispersion lenses to enhance uniformity, and PCBs can be incorporated carry a connector.

Cost is dependant on part size and how many different parts share the tool.

“A recent example of a design we manufactured using this technology was a high brightness, high uniformity white backlight with an integrated PCB and 2 pin connection, and about 35mm x 45mm,” said Heath. “Set-up NRE was under £1,500 with 500 pieces MOQ.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News