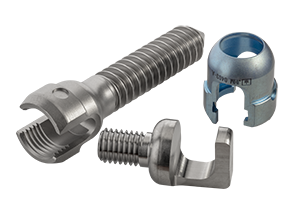

“Knowles specialises in small, intricate components and assemblies with tight tolerances and high precision,” according to the company.

“Its miniaturisation capabilities will provide med-tech OEMs with customised design, development and manufacturing services for miniature components and assemblies. Knowles will help companies scale production efficiently.”

It is offering:

- Stamping sheet metal with features ranging from 50μm to 254μm and 5μm tolerance

Plastic moulding for parts between 1 and 18mg, average thickness from 60 to 127μm with tolerances as low as 10μm

Plastic moulding for parts between 1 and 18mg, average thickness from 60 to 127μm with tolerances as low as 10μm- Coil winding, with its smallest coil so far measuring 0.45 x 1.06 x 2.36mm. Tolerance is ±3turn and ±10% resistance at 20°C.

- Micro cable assemblies

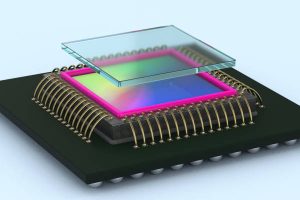

- Micro electronic assemblies

- Micro machining

Picking stamping as an example: stainless steel, aluminium, Mu metal, copper, tantalum and mylar are among the many materials that can be processed, using techniques including: bending and forming.

With electronic assemblies, many types of PCB, both rigid and flexible, can be loaded and soldered with fine-pitch LGA, BGA and micro BGA ICs, 0201 (metric, 008004inch) passives, tactile switches and other components, then assembled into housings with, for example, acoustic mesh, gaskets, under-filling, conformal coating and bonding.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News